Pressure swing adsorption air separation equipment

Membrane separation air separation series

Oil field special air separation equipment series

Pressure swing adsorption special gas Generator series

Purification of VCM waste gas by pressure swing adsorption

The technology for coke oven gas purification

The technology of Purification CO2 by PSA

The technology of Purification CO by PSA

The technology of Purification natural gas by PSA

The technology for Decarburizations through PSA

The technical of Purification of hydrogen by pressure swing adsorption

Compressed air purification equipment series

Freeze drying machine

No heat regenerative adsorption dryer

Micro heat regeneration dryer

Micro heat regeneration compressed air dryer

Compression blower heat zero gas consumption drier

Zero gas consumption isobaric adsorption dryer

Combined low dew point drier

High efficient oil remover

High efficiency oil-water separator

CJF Type Precision Air Filter

CDF Type Dust Fine Air Filter

CLT Type Activated Carbon Air Filter

Antibacterial Air Filter

High efficiency gas cooler

Dew point detector

Skid-mounted

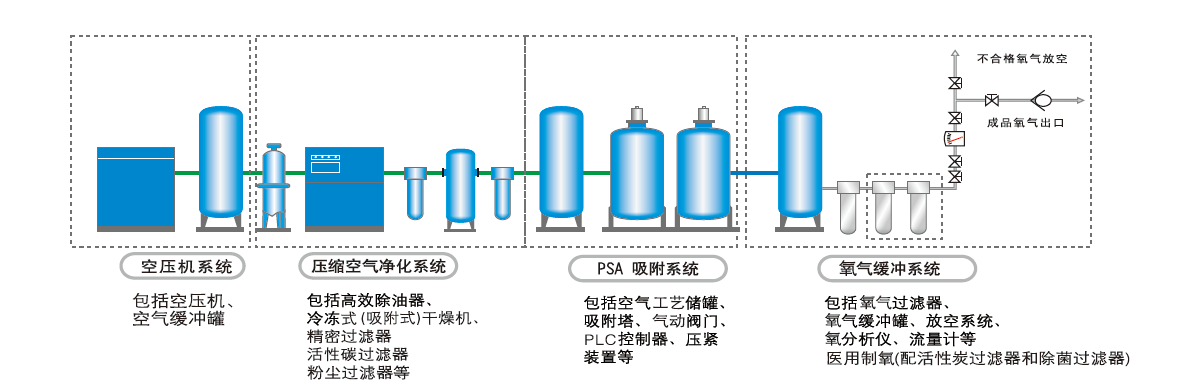

Tl0-y oxygen equipment is designed with PSA pressure swing adsorption principle. The oxygen is extracted from the air directly at room temperature with high-quality oxygen molecular sieve as adsorbent.

Working principle:

TLO oxygen equipment is carefully developed by using PSA pressure swing adsorption principle. With high-quality oxygen molecular sieve as adsorbent, oxygen is directly separated from air and prepared at room temperature. The compressed air after drying and purification is put into the adsorption tower with molecular sieve. Nitrogen, carbon dioxide, water and other elements in the air are absorbed in the solid phase of molecular sieve, while oxygen is enriched and exported in the gas phase due to the small adsorption amount. When the adsorbent reaches saturation, the pressure is reduced to make the zeolite desorption and regeneration so that the zeolite can be reused. Two adsorption towers are set up in the system, one tower for oxygen production and one tower for regeneration. The two towers are controlled by imported PLC to produce high-quality oxygen continuously.

Whole machine runs reliably:

Advanced oxygen production process design, scientific gas distribution structure, patented molecular sieve filling process, special protective measures of oxygen production molecular sieve and cylinder automatic pressure compensation device are combined organically, which is conducive to the long-term use of oxygen production molecular sieve. Continuous production is stable with imported PLC control system and imported pneumatic valve with a switching life of 3 million times, which is efficient and reliable. Ensure continuous and reliable operation of the device.

Advanced control system:

PLC control system, automation degree is high, can choose touch screen control system, which USES the human interface design, have shown more function, can be displayed online oxygen purity, parameters such as flow, pressure, fault signal, and can change operation parameters online, with remote monitoring, remote transmission signal, and remote key functions, high degree of automation, simple operation, can realize automatic unmanned, and DCS system and users from spreading.

Low operating cost:

Compared with other devices (including cryogenic oxygen, liquid oxygen and cylinder oxygen), PSA oxygen production costs are lower in small and medium sized devices.

Perfect after - sales service:

Perfect after-sales service system and distribution of marketing service network to ensure that every customer is assured of long-term use.

Oxygen production:3-200

Oxygen purity:93+2% (the standard type is 93%)

Oxygen pressure:0.1-0.4Mpa(can be Adjustable and pressurized)

Oxygen atmospheric dew point:-43degree